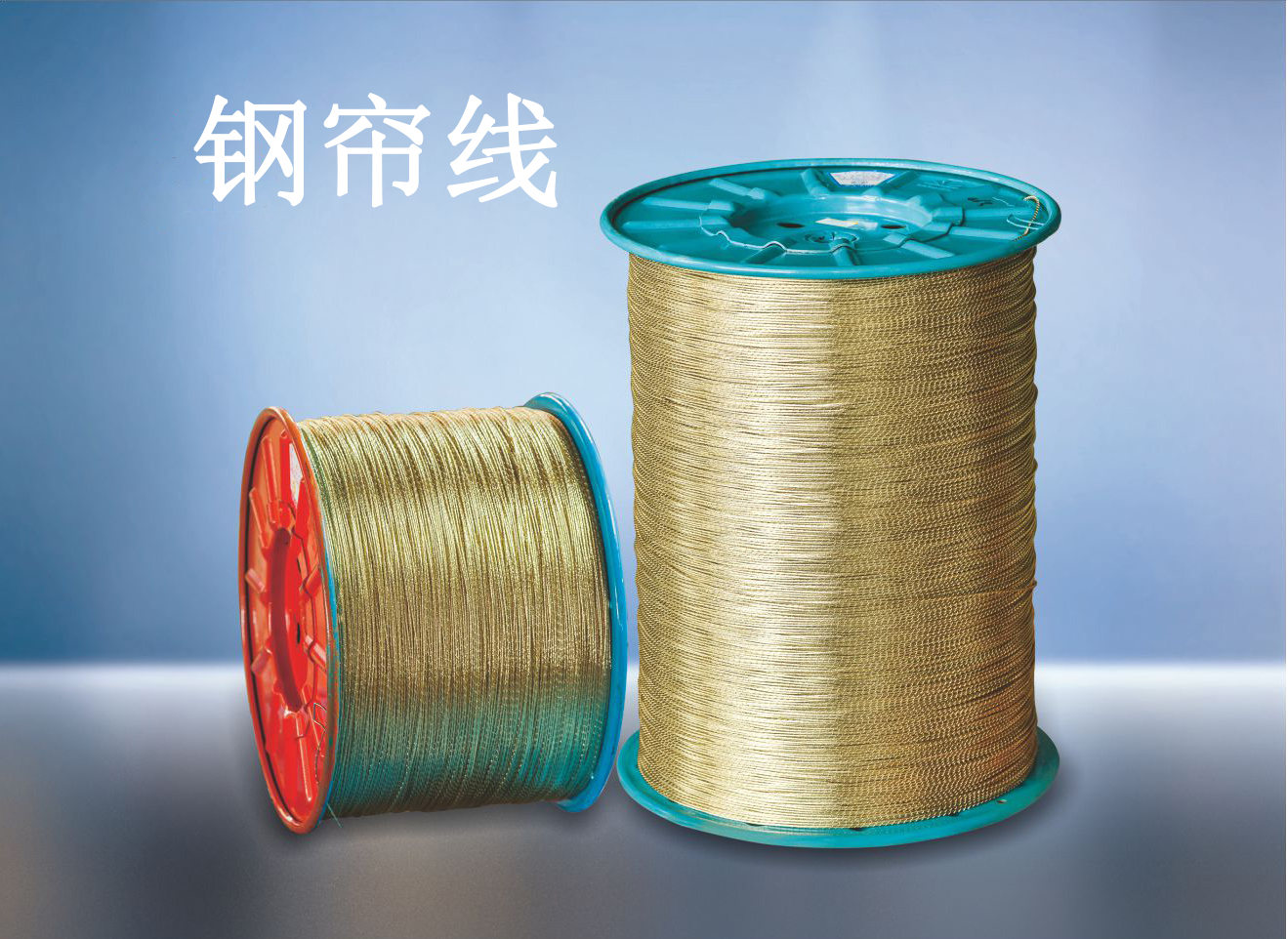

Steel cord

Steel cord is a kind of steel wire made from high-quality, high-carbon steel wire rod, which is drawn, coppe

Product Manual

Steel cord is a kind of steel wire made from high-quality, high-carbon steel wire rod, which is drawn, copper-plated, twisted and other processes. The surface is plated with brass to ensure the best adhesion between the steel wire and the rubber. Our company's steel cord products can meet the highest requirements of customers in various technical performance indicators, and are widely used in the rubber industry. Daye shares can not only meet the industry's international standards, but also meet the diverse needs of different customers.

Technical Parameters

| 结构 | 捻距 | 捻向 | 线径 | 破断力 | 线密度 |

| 3+9+15*0.225HT | 6.3±0.315/12.5±0.625 18±0.9 | Z/Z/Z | 1.38±0.069 | ≥3120 | 8.67±0.43 |

| 3+9+15*0.225ST | 6.3±0.315/12.5±0.625 18±0.9 | Z/Z/Z | 1.38±0.069 | ≥3485 | 8.67±0.43 |

| 3+9+15*0.22+0.15 | 6.3±0.32/12.5±0.63 18±0.9/3.5±0.18 | S/S/Z/S | 1.62±0.08 | ≥2700 | 8.5±0.25 |

| 3+9+15*0.175+0.15 | 5±0.25/10±0.5 16±0.8/3.5±0.18 | S/S/Z/S | 1.34±0.07 | ≥1680 | 5.42±0.27 |

| 3+9*0.22 | 6.3±0.32/12.5±0.63 | S/S | 0.92±0.046 | ≥1185 | 3.65±0.182 |

| 3+9*0.22HT | 6.3±0.32/12.5±0.63 | S/S | 0.92±0.046 | ≥1360 | 3.65±0.182 |

| 3+9*0.22+0.15 | 6.3±0.32/12.5±0.63 3.5±0.18 | S/S/Z | 1.18±0.06 | ≥1185 | 3.85±0.18 |

| 3+9*0.22+0.15HT | 6.3±0.32/12.5±0.63 3.5±0.18 | S/S/Z | 1.18±0.06 | ≥1360 | 3.85±0.18 |

| 3*0.24/9*0.225HT | 14±0.7/14±0.7 | S/S | 0.94±0.05 | ≥1445 | 3.94±0.2 |

| 3*0.22/9*0.20HT | 12.5±0.63/12.5±0.63 | S/S | 0.88±0.04 | ≥1185 | 3.17±0.16 |

| 3*0.22/9*0.20+0.15HT | 12.5±0.63/12.5±0.63 5.0±0.25 | S/S/Z | 1.11±0.055 | ≥1185 | 3.33±0.166 |

| 3*0.24/9*0.225+0.15HT | 12.5±0.63/12.5±0.63 5.0±0.25 | S/S/Z | 1.17±0.06 | ≥1445 | 4.10±0.21 |

| 3*0.15+6*0.27HT | 9±0.45/10±0.5 | S/Z | 0.85±0.040 | ≥1000 | 3.17±0.158 |

| 3*0.20+6*0.35 | 10±0.5/18±0.9 | S/Z | 1.13±0.03 | ≥1550 | 5.34±0.28 |

| 3*0.20+6*0.35HT | 10±0.5/18±0.9 | S/Z | 1.13±0.03 | ≥1850 | 5.34±0.28 |

| 1*0.365+6*0.35HT | 18±0.9 | S | 1.08±0.05 | ≥1860 | 5.42±0.27 |

| 2+7*0.22HT | 6.3±0.315/12.5±0.63 | S/S | 0.83±0.041 | ≥1010 | 2.74±0.137 |

| 2+7*0.30ST | 8±0.4/16±0.8 | S/S | 1.19±0.06 | ≥2005 | 3.89±0.2 |

| 3*7*0.20HE | 3.9±0.19/6.3±0.31 | S/S | 1.34±0.08 | ≥1360 | 5.77±0.23 |

| 3*3*0.20HE | 3.0±0.15/6.0±0.3 | S/S | 0.92±0.06 | ≥715 | 2.42±0.12 |

| 3*4*0.22HE | 3.15±0.157/6.3±0.31 | S/S | 1.18±0.059 | ≥940 | 3.95±0.2 |

| 3+8*0.33HT | 10±0.5/18±0.9 | S/S | 1.36±0.07 | ≥2650 | 7.48±0.37 |

| 3+8*0.35HT | 10±0.5/20±1 | S/S | 1.44±0.072 | ≥2860 | 8.44±0.422 |

| 3+8*0.33HT | 10±0.5/20±1 | S/S | 1.34±0.07 | ≥2940 | 7.48±0.37 |

| 3+8*0.22HT | 6.3±0.315/12.5±0.625 | S/S | 0.9±0.04 | ≥1240 | 3.35±0.16 |

| 5*0.25NT | 10±0.5 | S | 0.67±0.03 | ≥660 | 1.95±0.1 |

| 5*0.38HT | 18±0.9 | S | 1.34±0.08 | ≥1505 | 4.51±0.225 |

| 5*0.35HT | 17±0.85 | S | 0.94±0.047 | ≥1310 | 3.82±0.19 |

| 5*0.38HI | 14±0.7 | S | 1.030±0.051 | ≥1185 | 3.82±0.19 |

| 5*0.35HI | 14±0.7 | S | 1.19±0.06 | ≥1130 | 4.63±0.23 |

| 2+2*0.35ST | ∞/18±0.9 | -/S | 0.94±0.08 | ≥1175 | 3.06±0.15 |

| 2+2*0.32ST | ∞/16±0.8 | -/S | 0.83±0.06 | ≥1000 | 2.57±0.3 |

| 2+2*0.25HT | ∞/14±0.7 | -/S | 0.65±0.03 | ≥570 | 1.55±0.08 |

| 2+2*0.28HT | ∞/16±0.8 | -/S | 0.74±0.04 | ≥680 | 1.95±0.1 |

| 2+2*0.30HT | ∞/16±0.8 | -/S | 0.78±0.04 | ≥810 | 2.23±0.11 |

| 2+2*0.35HT | ∞/16±0.8 | -/S | 0.94±0.05 | ≥1025 | 3.03±0.15 |

| 2+1*0.25HT | ∞/11±0.55 | -/S | 0.63±0.03 | ≥425 | 1.16±0.06 |

| 2+1*0.30HT | ∞/14±0.7 | -/S | 0.75±0.04 | ≥610 | 1.67±0.08 |

| 3*0.28ST | 14±0.7 | S | 0.60±0.03 | ≥575 | 1.46±0.1 |

| 3*0.30ST | 16±0.8 | S | 0.64±0.03 | ≥670 | 1.67±0.1 |

| 3*0.32NT | 12.5±1 | S | 0.689±0.0215 | ≥550 | 1.76±0.088 |

| 3*0.38ST | 20±1 | S | 0.8±0.03 | ≥980 | 2.67±0.08 |

| 3*0.30HT | 16±0.8 | S | 0.65±0.03 | ≥610 | 1.68±0.08 |

| 3*0.27HT TR | 14±0.7 | S | 0.58±0.03 | ≥470 | 1.35±0.07 |

| 3*0.28HT TR | 16±0.8 | S | 0.6±0.03 | ≥480 | 1.46±0.07 |

| 2*0.30HT | 14±0.7 | S | 0.6±0.03 | ≥405 | 1.12±0.06 |

| 2*0.30ST | 14±0.7 | S | 0.6±0.03 | ≥445 | 1.12±0.06 |

| 2*0.30ST | 16±0.8 | S | 0.6±0.03 | ≥445 | 1.12±0.06 |

product manual

product manual technical parameters

technical parameters online consultation

online consultation