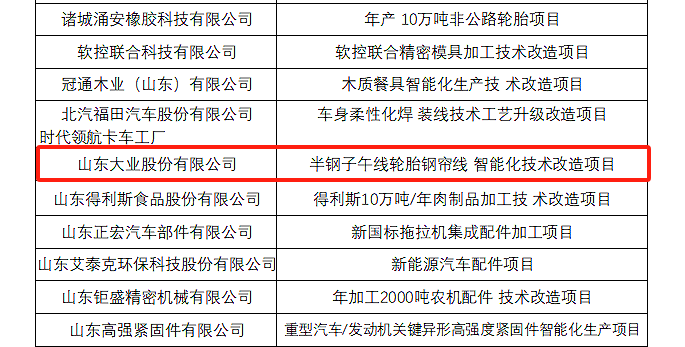

Recently, the Shandong Provincial Department of Industry and Information Technology and the Shandong Branch of the People's Bank of China announced the "2024 Shandong Province Enterprise Technology Transformation Key Project Guidance Catalogue", and the company's semi steel radial tire steel cord intelligent technology transformation project was successfully selected.

The technological transformation with green and intelligent as the main direction is becoming a powerful means for companies to break through the ice and gather strong momentum for high-quality development.

Machine replacement. The company has been undergoing intelligent transformation since 2019, with an investment of 1.09 billion yuan in the steel cord intelligent transformation project alone. The project was completed and put into operation in December 2021, increasing production efficiency by 10%, reducing labor by 20%, and increasing product qualification rate to over 99.8%. It can produce 150000 tons of high-performance tire steel cord annually, achieving sales revenue of 1.2 billion yuan and profits and taxes of 120 million yuan. The Steel Cord Intelligent Inspection and Distribution Center has upgraded the previous manual inspection to system automatic inspection through intelligent detection equipment. Through visual technology, it automatically reads the torsion and bow height values and transmits them to the system, eliminating errors and mistakes caused by manual inspection and preventing missed inspections. It not only achieves full inspection of product performance but also improves the reliability and stability of quality inspection, which is a major breakthrough in improving product quality.

Equipment upgrade. This technological transformation utilizes existing workshops, eliminates equipment such as manual single fiber transport vehicles, manual packaging machines, manual sealing machines, and manual inspection fixtures, and purchases 135 sets of intelligent equipment such as AGV transport vehicles, dual machine software, intelligent logistics systems, detection equipment, and scheduling systems. All produced finished products are transported to our intelligent inspection center through conveyor lines and elevators. Through intelligent AGV vehicles, intelligent path planning, obstacle avoidance, and charging are achieved according to the order receiving sequence, completing flexible production from multiple points to multiple points. To become the first demonstration and benchmark enterprise in the global industry to achieve full process intelligent manufacturing of intelligent logistics, intelligent inspection and matching, and intelligent packaging.

Finger pointing towards high-end. In 2021, the company was recognized by the Shandong Provincial Department of Industry and Information Technology as an intelligent digital workshop for steel curtain lines and a benchmark enterprise for intelligence in Shandong Province. After passing the expert appraisal organized by the China Petroleum and Chemical Industry Federation, it was determined that the company's "key technology research and application of digital manufacturing of steel cord" has reached the international advanced level, playing a leading role in the high-quality development of the steel cord industry.

During the 14th Five Year Plan period, the company will always adhere to the development concept of "technology leading enterprise development, innovation forging national brands", accelerate the pace of intelligent upgrading and transformation, fully implement high-end and international business development strategies, and make greater contributions to the progress and development of China's rubber skeleton material industry and high-performance green and environmentally friendly tire industry.