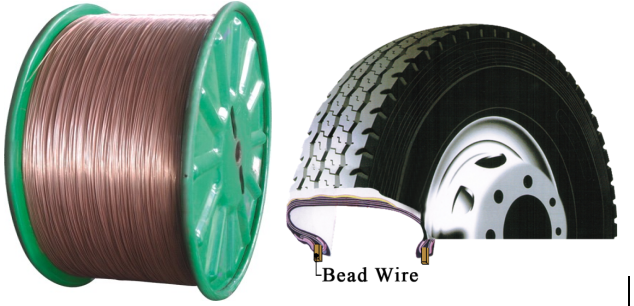

Recently, the international standard ISO 16650:2025 "Bead wire" led by China has been officially approved and released! As the project leader unit of this standard, the company shoulders the banner of international standard development with its technological strength, marking the successful transformation of China's technological achievements and industry experience in the field of tire bead wire into international consensus, and further demonstrating the leading discourse power of Chinese enterprises in the global rubber skeleton material industry.

The revision of the international standard ISO 16650:2025 "Bead Wire" will be officially approved in June 2023. The project is led by experts from the Metallurgical Industry Information Standards Research Institute as the convener of the working group. The company takes the lead in the discussion and drafting of core technologies throughout the process. After multiple rounds of technical consultations with domestic and foreign industry experts, a high degree of consensus has been reached on key technical indicators such as the tensile strength level, coating type, torsional performance, and adhesion test of tire bead steel wire. During this process, the company relied on more than 20 years of technical accumulation in the field of tire bead steel wire, and integrated millions of sets of production testing data and multiple patented technological achievements accumulated through independent research and development into the standard revision, providing solid support for the scientific and forward-looking nature of the standard.

As a "National Manufacturing Single Champion Demonstration Enterprise" in the field of tire bead wire, the company's technical strength has long been recognized by the industry - the company is one of the world's largest tire bead wire production enterprises, occupying more than 35% of the domestic market share and nearly 20% of the global market share; Steel cord production capacity ranks third globally and second domestically; Rubber hose steel wire has also become one of the major global manufacturers. The company's products have long been supplied to the world's top ten tire companies such as Michelin, Bridgestone, and Goodyear, as well as domestic leading tire manufacturers such as Zhongce, Linglong, and Sailun, serving hundreds of large and medium-sized customers worldwide. The leading international standard revision this time is a concentrated reflection of the company's technical strength and industry status.

This ISO standard revision is a precise upgrade made to meet the development needs of the global tire industry for "lightweight, low rolling resistance, and high service life": based on the current national standard for bead wire in China, a higher level of tensile strength index has been added to meet the performance requirements of high-end tires for skeleton materials; Delete the type of pure copper coating to comply with the trend of green manufacturing and cost optimization; Optimize the yield to strength ratio, torsional performance requirements, and adhesion testing methods to further standardize the product quality evaluation system. These revised contents not only provide unified technical guidelines for the production and trade of global bead wire, but also promote China's advanced technological solutions in this field to the world, clearing technical barriers for China's high-end steel wire products to "go global".

The ability to shoulder the responsibility of international standard setting stems from the company's ultimate pursuit of innovation. As a national high-tech enterprise, national intellectual property demonstration enterprise, and national green factory, the company has established 9 research and development platforms at or above the provincial and ministerial level, including the National Enterprise Technology Center and the National Rubber Skeleton Material Standard R&D Base. It has accumulated 259 patent authorizations, including 109 domestic invention patents and 9 international invention patents, and has led and participated in the formulation and revision of 21 international standards, national standards, and other standards. From winning the second prize of China Petroleum and Chemical Industry Federation's Science and Technology Progress Award for the "Industrialization Technology of Ultra High Strength Bead Wire for Ten Thousand Tons/Year Radial Tires", to being selected for the National Torch Plan for the "High Tin Bead Wire Project for High Performance Tires", and leading the revision of the latest version of the national standard for bead wire, to this international standard revision, Daye Group has always driven industry progress with technological innovation, practicing the development concept of "technology leading enterprise development, innovation forging national brands".

The release of the international standard ISO 16650:2025 "Bead Wire" is not only an important milestone in the company's development process, but also an important step for China's rubber skeleton material industry to move towards the high-end of the global value chain. Facing the "15th Five Year Plan" and the future, the company will continue to promote intelligent, green, and high-end upgrades, accelerate the implementation of internationalization strategies, and strive to achieve a total production capacity of over 1.6 million tons and sales revenue of over 12 billion yuan by 2030, contributing more "Chinese solutions" to the green upgrading and technological progress of the global tire industry!