On December 4th, the second working meeting of the aviation tire standardization sub committee of the 7th National Tire and Rim Standardization Technical Committee was successfully held in Zhucheng. Gong Haixia, Deputy General Manager of Shandong Daye Co., Ltd., attended the meeting as an observer. One of the core topics of this conference, the discussion on the standard of cable shaped bead wire for aviation tires, has become a focus of the industry. Shandong Daye Co., Ltd., as a leading enterprise in the field of tire skeleton materials, deeply participated in the discussion throughout the process and provided key support for the improvement of industry standards with excellent technical accumulation, standardization achievements and production strength, winning high recognition from all attending expert committee members.

The technology of cable type tire bead steel wire has long been monopolized by foreign countries. Through continuous independent research and development, key equipment transformation and upgrading, the company has successfully broken through technical barriers and achieved independent production of products. The company innovatively adopts an intelligent production mode of "one person controlling multiple devices", greatly releasing labor and achieving a qualitative leap in production efficiency. In the quality inspection process, the company's independently developed automatic testing equipment not only completely replaces traditional manual measurement methods, but also achieves precise detection of key indicators such as product flatness and ellipticity, synchronously achieving closed-loop control of the entire process of automatic detection, data storage, and data analysis, ensuring the stability and consistency of product performance from the source. At present, the cable type bead wire produced by the company has formed a rich product matrix and is widely used in various fields such as drones, light rail, bicycles, motorcycles, automobiles, racing cars, buses, and aircraft tires. With excellent performance, it has won high recognition from mainstream tire enterprises at home and abroad.

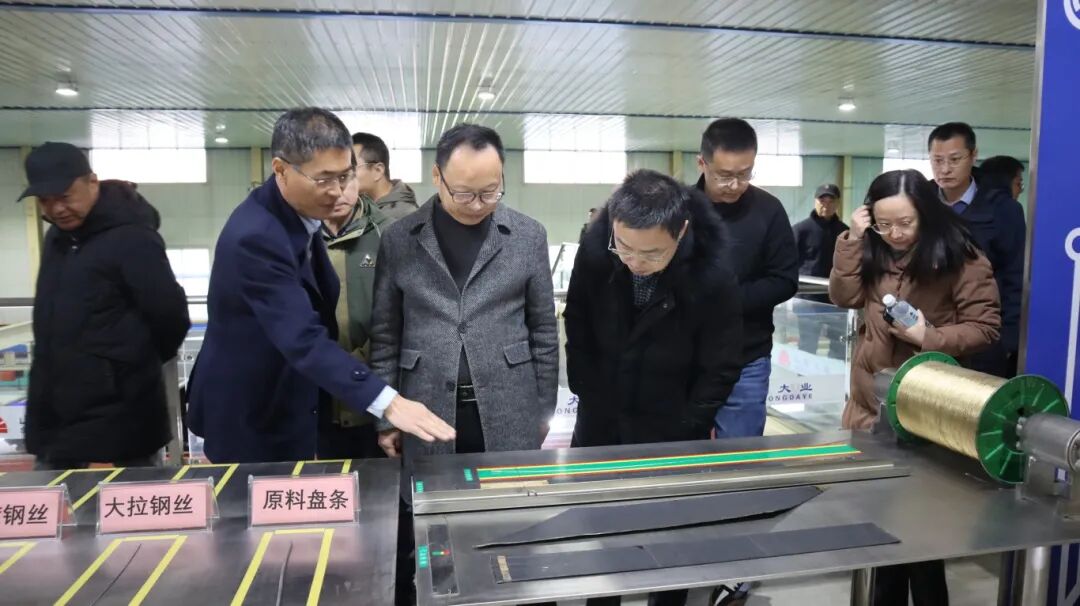

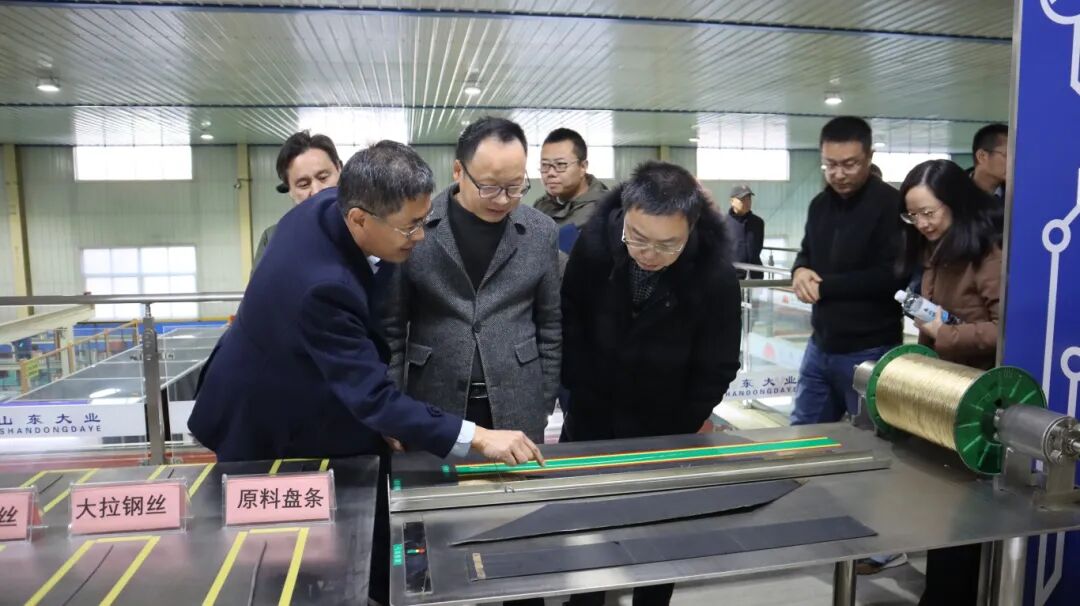

As a core participant and technology leader in the development of industry standards, Daye Group has been invited to be an important exchange participant in this seminar. During the conference, all expert committee members visited the company specifically for guidance and in-depth inspection of the digital production workshop and intelligent inspection center for steel curtain lines. They conducted on-site visits to the entire process of research and production of cable shaped bead wire for aviation tires. The company's technical team reported in detail to the inspection team on the core advantages of the product in material selection, process innovation, quality control, etc. - compared with ordinary bead wire, cable type bead wire can accurately maintain its own shape during the vulcanization process. Its unique structural design endows the product with strong stability, enabling it to maintain excellent mechanical properties. At the same time, it also has outstanding advantages such as light weight, uniform force distribution, and green environmental protection, fully adapting to the harsh use requirements of aviation tires in extreme situations.

In the standard discussion session, the demand for the development of national standards for cable type bead wire for aviation tires has become a focal point of discussion. At present, there is no specific national standard for cable type bead wire used in aviation tires in the industry, which leads to a lack of unified technical basis for high-end products in production, quality control, market application and other aspects. This to some extent restricts the standardized upgrading of China's aviation tire industry and the independent and controllable development of core materials. In this context, it is of great industry necessity and practical significance for Daye Group to proactively initiate the project and oversee the formulation of this standard. This measure not only fills the standard gap in the field of cable type bead wire for domestic aviation tires, providing unified technical guidance for product research and development, production, and testing, but also promotes the formation of a standardized development order in the industry, laying a solid standard foundation for the quality improvement and industrial upgrading of core materials for aviation tires in China. It has been highly recognized and actively supported by all expert committee members.

At present, the domestic large aircraft industry is entering a period of vigorous development, and aviation tires are the "wheel of life" to ensure flight safety. As the core skeleton material of aviation tires, the localization of cable shaped bead wire is a key link to ensure the integrity of the domestic large aircraft industry chain, reduce external dependence, and enhance international competitiveness. Without domestically produced core materials, the "independent controllability" of domestic large aircraft will be greatly reduced. The technological breakthroughs and large-scale production of Daye Group provide a solid guarantee for China's aviation tire industry to achieve independent and controllable core materials, and also inject strong impetus into the high-quality development of the domestic large aircraft industry.

Throughout its history, Daye Group has always adhered to the development philosophy of "innovation driven and standard led", taking standardization work as the core driving force for promoting high-quality development of enterprises. In recent years, it has led and participated in the formulation and revision of 21 international standards, national standards, industry standards, and group standards. In the future, the company will take this seminar as an opportunity to continue deepening cooperation with industry experts, research institutions, and upstream and downstream enterprises, focusing on technological innovation and standard upgrading of cable type bead wire for aviation tires. With a more comprehensive product matrix, higher standard requirements, and better product quality, the company will serve the global tire industry, help China's aviation tire industry achieve iterative upgrading, and contribute greater strength to ensuring national aviation safety and enhancing the global competitiveness of China's aviation tire and large aircraft industry!